STRATEGIC MARKET ANALYSIS & MARKET RESEARCH FOR MECHANICAL ENGINEERING

As a market research company, MEYER INDUSTRY RESEARCH produces customized market analyses and market studies for the mechanical and plant engineering sectors. Our clients include OEMs, suppliers, and service providers in the mechanical engineering market.

A market analysis in mechanical engineering examines, for example, market size, market growth, market potential, competitive situation , potential customers as well as trends and developments in the market.

Market research in mechanical engineering provides the basis for evaluating market potential for innovations , developing new customers , strategic orientation or competitive analysis.

EXAMPLES OF MARKET RESEARCH PROJECTS IN MECHANICAL ENGINEERING

market and competitive analyses for numerous manufacturers, suppliers, and service providers in the mechanical engineering sector since 2007. Please click on the keywords to learn more about exemplary market research projects in mechanical engineering:

The global machine vision market was valued at approximately €8-9 billion in 2018. The market is expected to grow by approximately 7% annually until 2024. This growth is driven by increasing levels of automation in manufacturing and the increasing use of quality control systems based on machine vision. The automotive industry remains the largest consumer of machine vision systems, accounting for 22% in 2018. We analyzed the machine vision and robot vision market for a medium-sized mechanical engineering company, developing the basis for our client's future market development strategy in the field of machine vision.

Digital twins are digital representations of people, machines, plants, processes, systems, and entire production processes. They are increasingly used in research, development, and production . Market studies expect the global market for digital twins to grow from approximately USD 3-6 billion (EUR 2.7-5.5 billion) today to approximately USD 15-20 billion (EUR 13.6-18.1 billion) in 2023/2025. The studies forecast annual growth rates of 28-37% (CAGR). For our client, a medium-sized special-purpose machine manufacturer, we investigated the market potential in the digital twin market. The market analysis served as the basis for the long-term development of the client's corporate strategy.

Our client, a global manufacturer of high-precision machining centers for the automotive industry, commissioned us to systematically identify foundries, machining centers, and assembly plants for electric motor housings for electric vehicles. The client sees this customer group as a high-growth target group and plans to target the identified companies with suitable machine solutions based on our analyses.

For a supplier, we examined the global market for industrial robots, identified the leading manufacturers worldwide, and analyzed market trends. Based on the market analysis, the client was able to expand its business in this area.

The international market for tool grinding machines is highly competitive. A medium-sized manufacturer of tool grinding machines also experienced this painfully when it was forced to file for bankruptcy amid market turmoil. For two investment companies interested in acquiring and continuing the medium-sized company, we conducted a detailed market study examining the global market situation, international sales markets such as China and Italy, the competitive structure, and key customer requirements. Through interviews with more than 20 tool grinding companies and market experts, we were able to draw a precise and reliable picture of the acquisition candidate's market position. Based on the results of our analysis, the investors decided to purchase and continue the company, thus securing numerous jobs.

We supported our client, an international manufacturer of materials testing machines, in its planned market entry into Germany and Europe by conducting customized market and company analyses. The focus was on destructive materials testing systems.

For a manufacturer of linear technology components, we examined the market situation, the leading suppliers in the market, potential target customers, and their requirements. The analysis serves as the basis for the market expansion strategy.

Our client, a medium-sized supplier of precision parts manufactured on 5-axis systems, was considering the purchase of several new large milling machines for machining large components made of aluminum, titanium, and stainless steel. Since the investment, including the construction of the new production hall, was of a critical size for the medium-sized company, management commissioned us to conduct a systematic market analysis prior to the purchase. We examined the potential, customer needs, and requirements for large 5-axis milled parts in the aviation, machine components, energy technology, maritime drive technology, and vacuum technology sectors, among others. More than 50 interviews with buyers and decision-makers at potential target customers in these industries provided a reliable assessment of the market potential, opportunities, and risks.

For a machine manufacturer's innovative new development in the field of waterjet cutting, we examined the market potential, competitive situation, and customer requirements in the target market. Through more than 30 in-depth interviews with numerous potential users in the contract manufacturing and supplier industries, we gained solid insight into the market for waterjet cutting systems.

For a newly developed system for the automatic cleaning of conveyor chains in overhead conveyor systems, we examined the market potential, competitive situation, customer requirements, and barriers to market entry. Through interviews with technical and production managers at powder coating companies, large paint shops, and foundries, we developed a solid foundation for the client's planned market entry in the German-speaking and European markets.

For a mechanical engineering company, we compiled a comprehensive list of contract cutting companies currently using waterjet cutting machines, laser cutting machines, or plasma cutting machines. The list serves as a basis for the client to systematically approach new customers in the target market.

For a supplier, we analyzed market potential in various segments of the global plastics and rubber machinery market. Through interviews with potential target customers, we systematically analyzed and evaluated the potential and their needs.

For an automation technology manufacturer, we analyzed market potential in the packaging machine sector, identified the leading manufacturers in the packaging machine market, and analyzed market trends. This analysis served as the basis for ongoing market monitoring.

For a supplier in the electric motor market, we examined market size, leading players, as well as trends and requirements in the electric motor market.

For a supplier of system components in the drive technology market, we investigated market potential, leading manufacturers and customers, as well as requirements and development trends in the drive technology market. Among other things, relevant requirements and trends were identified through more than 20 interviews with decision-makers in the drive technology sector. Based on the project results, the client is systematically expanding its sales activities in the drive technology market.

For a global supplier in the transmission market, we investigated expansion potential, leading potential customers and manufacturers, as well as customer requirements and market trends in the transmission market. Among other things, we conducted in-depth interviews with decision-makers in the transmission market to gather customer requirements and development trends. Based on the analysis results, our client is systematically expanding its sales activities in the transmission market.

For a supplier in the electric motor market, we investigated market size, leading players, as well as trends and requirements in the frequency converter and rectifier market.

For a supplier in the mechanical engineering sector, we investigated the market for servo motors, gearboxes and servo controllers for a planned new product launch.

For a manufacturer of direct drives (linear motors, torque motors), we analyzed market potential and the competitive situation in various application areas of mechanical engineering. The analysis results formed the basis for the targeted expansion of the manufacturer's activities in Germany.

We analyzed the compressor and compressed air technology market for a mechanical engineering supplier. The analysis served as the basis for systematically developing this market segment.

For a supplier in the mechanical engineering sector, we analyzed the market for pumps (metering pumps, centrifugal pumps, gear pumps, and vacuum pumps). This analysis served as the basis for systematically developing the market segment.

The market for service robots in professional applications (e.g., logistics, professional cleaning, medical technology) recently totaled approximately 132,000 units annually worldwide and grew at a double-digit rate. Dynamic growth of around 10% per year is also expected for the coming years. The trend is clearly toward autonomous systems with sensor technology and intelligence. The market offers numerous opportunities for suppliers and component manufacturers from various sectors: In the future, central computers must be able to process embedded vision and multiple signals. Battery and power management, as well as (wireless) charging technology, are other critical components in the automation of mobile robots. For our client, a large mechanical engineering company with high automation expertise, we examined the market for service robots and developed options for entering this fast-growing market.

Condition monitoring systems enable the continuous monitoring of the condition of machines and systems to increase availability and detect impending failures in a timely manner. The market is evolving toward full-service concepts that combine hardware, software, cloud solutions, and increasingly, complementary services. The role of artificial intelligence (AI) and new parameters for predicting machine health is steadily increasing. In this innovative market, we examined the international market and competitive environment for a leading manufacturer of condition monitoring systems.

For the automated handling of particularly sensitive goods, e.g., in semiconductor manufacturing, battery or fuel cell production, or the optical industry, so-called electrostatic chucks can be an alternative to the currently predominantly used vacuum grippers or special grippers. Electrostatic chucks can be used in cleanrooms and enable the handling of particularly thin, perforated, or fragile components. For a Japanese developer of these chucks, we prepared the market entry in Germany with a customized market analysis in the field of handling technology. The market analysis examined nine relevant application areas and their technical requirements and identified the key target customers in the focus industries in Germany.

Autonomous mobile robots (AMRs) autonomously transport goods and production materials in warehouses and production halls. Thanks to sensor technology, they can navigate safely even in dynamic environments, avoid obstacles, and independently reach different destinations. The market for AMRs is clearly a growth market: By 2025, the market is expected to grow by 40% annually in terms of unit volume, reaching approximately 572,000 units annually worldwide. For our client, a major supplier in the sensor technology sector, we analyzed growth potential in the AMR market and examined leading technology companies in the market, such as Mobile Industrial Robots and Robotize.

Global battery manufacturing capacity (Li-ion) is expected to rise from 200 GWh in 2018 to approximately 600-650 GWh in 2023. Asia, particularly China, will continue to dominate as a manufacturing location, but Europe is also building significant production capacity. The significant increase in battery manufacturing capacity is creating attractive market opportunities for machine manufacturers with specific expertise in building battery production facilities. For our client, a medium-sized special-purpose machine manufacturer, we conducted a market analysis for battery manufacturing worldwide, examining opportunities and growth potential for further developing their corporate strategy.

The market for fuel cells is relatively small so far, with approximately 75,000 units produced worldwide, and applications are primarily found in the stationary sector. Optimistic forecasts primarily anticipate a rapid ramp-up of the market for fuel cell vehicles. According to this forecast, approximately 300,000 vehicles could be produced worldwide as early as 2025. By 2030, as many as 2 million fuel cell vehicles could be built annually. In this scenario, the expansion of production capacity in the fuel cell sector could become an attractive growth market for specialized machine manufacturers: The high number of cells per fuel cell stack leads to high assembly costs. As volumes increase, processes must be automated and industrialized. Against this backdrop, a medium-sized automation specialist commissioned us to conduct a structured analysis of the opportunities and risks in the global market for fuel cell production systems.

The production of gears for vehicle transmissions will grow only modestly in the coming years, at approximately 1-2% per year. Against the backdrop of hybridization and electrification of vehicle drives, gear and transmission manufacturing is facing dynamic change. In addition to a few transmission production sites of OEMs such as Daimler, VW, or Opel, a few larger suppliers such as ZF, Getrag/Magna, or IMS Gear dominate the transmission manufacturing market. Against this backdrop, we examined the market situation and potential starting points for a successful entry into the European market for our client, an Asian manufacturer of straightening tools for transmission production.

For a mechanical engineering supplier, we analyzed the market for hydraulic systems and hydraulic components (hydraulic cylinders, hydraulic motors, hydraulic pumps, hydraulic units, and hydraulic systems). This analysis served as the basis for systematically developing the market segment.

For a supplier in the pneumatics industry, we examined the market for pneumatic systems and pneumatic components (pneumatic cylinders, pneumatic valves, compressed air maintenance units, pneumatic sensors). The results served as a basis for identifying new potential customers in the market and for the company's strategic development in the pneumatics sector. Among other things, we conducted approximately 20 expert interviews with leading market participants in the pneumatics sector and identified future trends and requirements.

For a mechanical engineering supplier, we analyzed the market for continuous conveyors and other warehouse technology systems. This analysis served as the basis for systematically developing this market segment.

For a mechanical engineering company operating in the stone production sector, we analyzed the market situation, key suppliers, and trends in the stone production equipment market. The analysis served as the basis for implementing a buy-and-build strategy for the company.

For a mechanical engineering company, we analyzed the potential of the emerging market for water technologies (water treatment, water filtration) in the industrial and municipal sectors. The analysis served as the basis for the company's strategic diversification into the water sector.

For a supplier in the field of automation technology, we examined the market situation for plant engineering in the biotech and life sciences industry worldwide.

For a supplier in the field of automation technology, we examined the market situation of plant engineering in the food and beverage industry worldwide.

For a system supplier in the machine tool market, we analyzed market potential, key target customers and manufacturers, the strategic positioning of competitors, as well as customer requirements and market trends. To gain a deep understanding of customer requirements, we conducted more than 20 expert interviews with decision-makers at machine tool manufacturers. Based on the project results, the client is further expanding its marketing and sales activities in the machine tool market.

We analyzed the market for industrial profiles for a manufacturer of aluminum profiles. As part of the study, we compiled data on market size and development, key application sectors, key suppliers in the market, and industry trends and developments.

For a service provider in the mechanical engineering sector, we analyzed the status of Industry 4.0 in mechanical and plant engineering and assessed the role of Manufacturing Execution Systems in this context.

For a manufacturer of converter technology, we analyzed the market size, competitive situation, and market trends in the European market. The analysis served as a basis for the supplier's targeted strategic development.

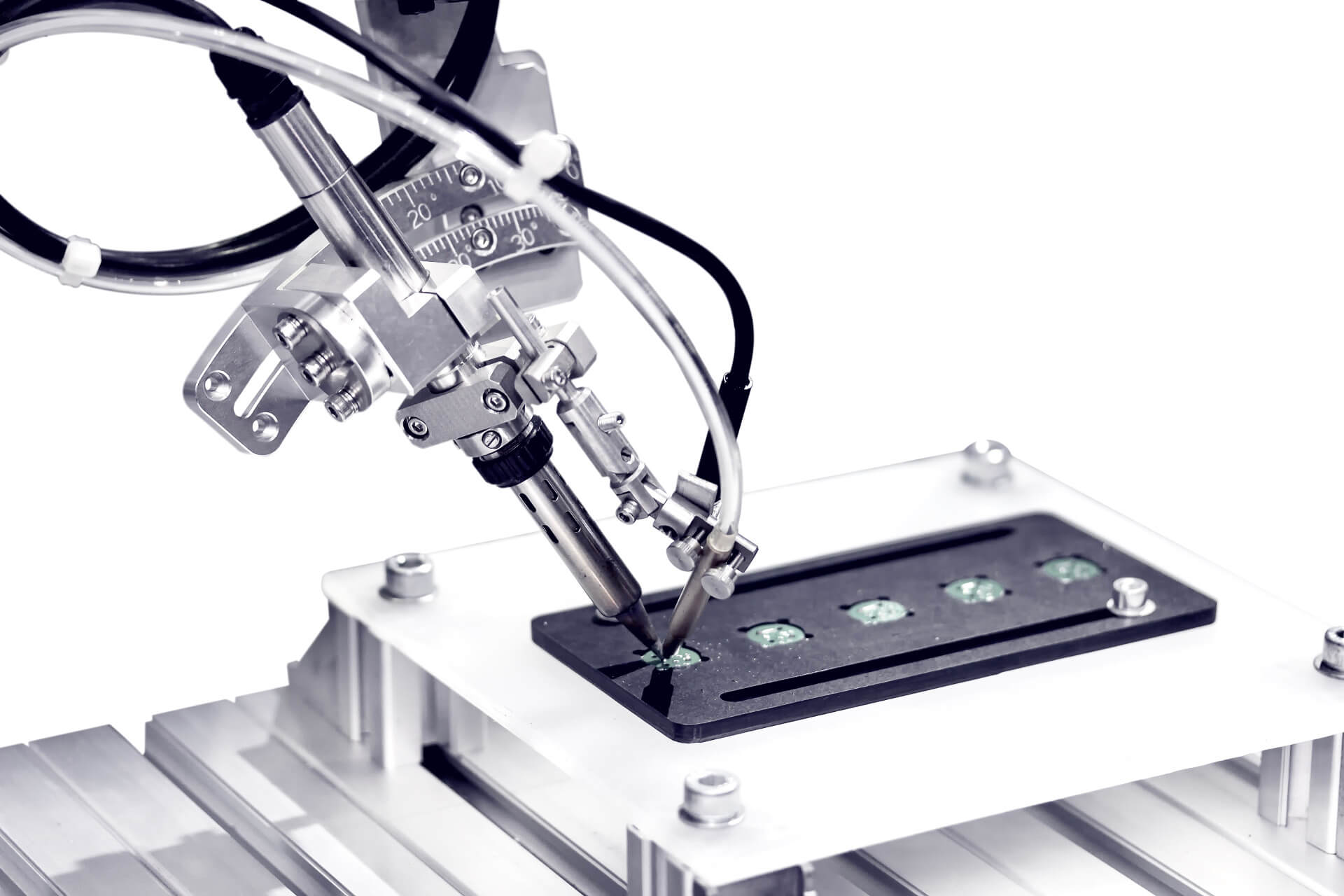

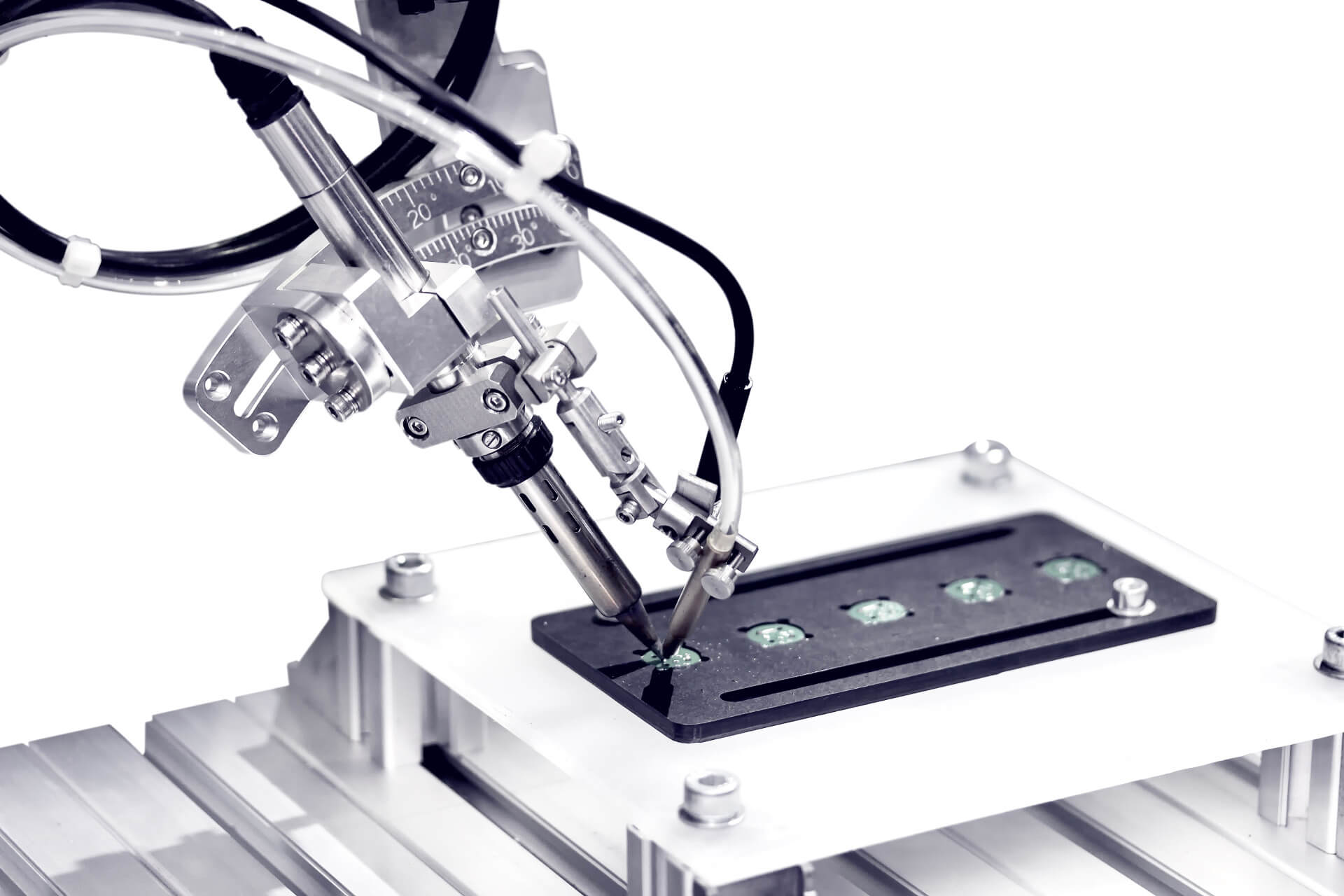

For an innovative industrial robot for precise small-part assembly, we analyzed the market potential, competitive situation, and requirements of key user industries in the German market. This analysis served as the basis for a public funding decision and paved the way for the approval of additional funding for development to market readiness.

For a global manufacturer of lead anodes for metal recovery electrolysis, we analyzed market potential, competitive situation, and customer needs in Europe, the USA, and South America. Based on our analyses, the manufacturer is continuing its international expansion in the market.

For an international supplier in process automation, we examined the global market situation, development forecasts, and key trends in coal-fired power plants. The market analysis formed the basis for the company's strategic development decision.

For a consulting firm, we analyzed value creation structures and development trends at selected surface technology companies. The information was used for benchmarking.

For an engineering firm, we examined the market for elevators and escalators in selected countries. The analysis included research on market data and growth prospects.

For a plant manufacturer specializing in innovative flood protection systems, we examined the market in selected countries. The analysis examined market potential, competitors, and growth prospects, identified potential sales partners and customers, and evaluated technical trends in the market. Based on the analysis, the client is currently systematically expanding its sales activities in the target markets.

On behalf of a globally active plant manufacturer specializing in sophisticated large-scale valves and valves without housing, we surveyed the market in selected countries. The study systematically identified target customers and sales partners from the wastewater technology sector and interviewed them regarding potential collaborations. Based on the results, the customer is currently expanding its international sales activities in the field of valves without housing.

For a supplier of hydraulic and pneumatic components, we examined the global market for construction machinery and analyzed the competitive situation in the construction machinery market from the client's perspective.

As part of a market entry project, we analyzed the market for powertrain test benches, engine test benches, and chassis test benches for our client, a medium-sized manufacturer of customized electric motors. Of particular relevance was the currently rapidly growing market for electric motor test benches. The extensive development activities of all OEMs and many suppliers in the field of electromobility are leading to a high demand for corresponding test bench technology and suitable high-speed test bench motors.

Fiber-reinforced plastics such as CFRP are used in a growing number of applications in automotive, mechanical engineering, aerospace, and medical technology. For our client, we investigated the market potential for a newly developed CFRP material characterized by exceptional stability, low weight, high surface resistance thanks to a special coating, and other unique selling points. The analysis examined possible applications and market opportunities and identified potential customers and cooperation partners for the use of this innovative material in the fiber-reinforced plastics market.

MARKET ANALYSIS MECHANICAL ENGINEERING GERMANY: TOP 100 RANKING

The new German Mechanical Engineering Market Analysis 2020 by MEYER INDUSTRY RESEARCH, published in March 2020, provides an overview of the 100 leading mechanical engineering companies in Germany, their revenue and employee figures, and data on the industry's profitability. The study is available for free download on our website.

Industry diversity – from global players to hidden champions: Whether machine tools, packaging machines, or plastics and rubber processing machines – German machine manufacturers are among the leaders in the global market. Our market study of the top 100 machine manufacturers in Germany highlights well-known global players such as GEA, Voith, and KUKA. At the same time, our ranking of Germany's leading mechanical engineering companies also includes numerous hidden champions, which also employ hundreds or thousands of people and are among the global market and technology leaders within their machine categories.

Download our free German Mechanical Engineering Market Analysis 2020 as a PDF here

FOCUS: DEMANDING NICHES AND INNOVATIVE TECHNOLOGIES

Our market analyses in mechanical engineering often focus on niche markets, innovations, and technologically demanding topics.

For market research in the mechanical engineering sector, we apply a proven, systematic research approach that incorporates all relevant data sources.

For sophisticated mechanical engineering market analyses, we utilize our extensive network of expert contacts, through which we generate valuable, in-depth information on markets, potential, and trends.

EXPERIENCE SINCE 2007 – OUR REFERENCES

Managing directors, sales managers, and strategy and business development managers at more than 100 client companies rely on our meticulous market analyses for one key reason: the uncompromising quality and reliability of our market analysis results. Our discerning clients also value the personal and open collaboration with our team, as demonstrated by their numerous testimonials – please see for yourself.

INDIVIDUAL CONSULTING FOR YOUR COMPANY ANALYSIS

Trustful personal cooperation and the high quality and reliability of our analyses are top priorities at MEYER INDUSTRY RESEARCH.

We would be happy to provide you with an in-depth, non-binding consultation prior to a potential collaboration , including a personal on-site consultation upon request. We look forward to receiving your inquiry and will be happy to prepare a customized quote for you!